Self-pressure regulating valve

Self-pressure regulating valve

Nominal diameter: DN20 ~ 300mm

Nominal pressure: PN16 ~ 64MPa

Temperature: ≤ 350 ℃

Main material: ZG230-450 ZG1Cr18Ni9Ti ZGOCr18Ni12M02Ti

Product description:

ZZY-type self-acting pressure regulating valve without external energy, the use of the media itself as the power of the media to be adjusted, the introduction of the actuator control spool position, change both ends of the pressure and flow, so that before the valve (or valve) pressure stability. With sensitive, good sealing, small pressure set point fluctuations, etc., are widely used in gas, liquid and vapor pressure regulator decompression regulator or automatic control.

This series of products have a single seat (ZZYP), sleeve (ZZYM), two-seat (ZZYN) three structures; executive agencies are film, piston two; role type decompression valve with the pressure regulator (B) And pressure relief valve with pressure regulator (K type). Product nominal pressure rating PN16, 40, 64; body diameter range DN20 ~ 300; leakage levels are II, IV and VI third gear; flow characteristics for quick opening; pressure sub-adjustment from 15 ~ 2500kPa. Can be combined as needed to meet the needs of user conditions.

Features:

1, Self-operated pressure control valve without additional energy, can work in a non-electric gas-free place, both convenient and energy saving.

2, the pressure range of small and cross each other, adjust the high precision.

3, the pressure setting can be set continuously during operation.

4, after the valve pressure regulator, the pressure before the valve and valve pressure ratio of 10: 1 ~ 10: 8.

5, rubber diaphragm detection, the implementation of high precision detection, action sensitive.

6, the use of pressure balance mechanism, so that the control valve responsive and precise control.

Part Information:

Body: ZG230-450 ZG1Cr18Ni9Ti ZGOCr18Ni12M02Ti

Spool: 1Cr18Ni9Ti 0Cr18Ni12M02Ti

Seat: 1Cr18Ni9Ti 0Cr18Ni12M02Ti

Stem: 1Cr18Ni9Ti 0Cr18Ni12M02Ti

Film cap: A3 A3 stainless steel coated with tetrafluoroethylene

Packing: flexible graphite Teflon

Rubber diaphragm: nitrile, B C, fluorine, oil-resistant rubber

Technical Parameters:

◆ main technical parameters and performance indicators

Nominal diameter DN (mm) | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | ||||||||||

Rated flow coefficient Kv | 7 | 11 | 20 | 30 | 48 | 75 | 120 | 190 | 300 | 480 | 760 | 1100 | 1750 | ||||||||||

Rated travel (mm) | 8 | 10 | 14 | 20 | 25 | 40 | 50 | 60 | 70 | ||||||||||||||

Nominal pressure PN (MPa) | 1.6, 4.0, 6.4 | ||||||||||||||||||||||

Pressure adjustment range (kPa) | 15 ~ 50 40 ~ 80 60 ~ 100 80 ~ 140 120 ~ 180 160 ~ 220 200 ~ 260 | ||||||||||||||||||||||

Flow characteristics | Go ahead | ||||||||||||||||||||||

Adjustment accuracy (%) | ± 5 | ||||||||||||||||||||||

Operating temperature (℃) | ≤ 350 | ||||||||||||||||||||||

allow Leakage | Hard seal (l / h) | Single seat: ≤ 10 -4 valve rated capacity (Class IV); double seat, sleeve ≤ 5X10 -3 valve rated capacity (Class II) | |||||||||||||||||||||

Soft seal (ml / h) | 0.15 | 0.30 | 0.45 | 0.60 | 0.90 | 1.7 | 4.0 | 6.75 | 11.10 | 16.0 | |||||||||||||

Decompression ratio | maximum | 10 | |||||||||||||||||||||

Min | 1.25 | ||||||||||||||||||||||

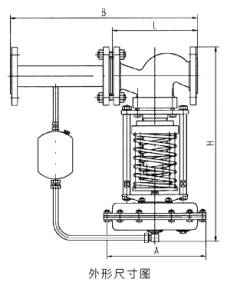

◆ Dimensions and weight

Nominal diameter DN | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | ||

Flange take over size B | 383 | 512 | 603 | 862 | 1023 | 1380 | 1800 | 2000 | 2200 | ||||||

Flange face distance L | 150 | 160 | 180 | 200 | 230 | 290 | 310 | 350 | 400 | 480 | 600 | 730 | 850 | ||

Pressure force Tune Festival Fan Wai kPa | 15 ~ 140 | H | 475 | 520 | 540 | 710 | 780 | 840 | 880 | 915 | 940 | 1000 | |||

A | 280 | 308 | |||||||||||||

280 ~ 500 | H | 455 | 500 | 520 | 690 | 760 | 800 | 870 | 880 | 900 | 950 | ||||

A | 230 | ||||||||||||||

120 ~ 300 | H | 450 | 490 | 510 | 680 | 750 | 790 | 860 | 870 | 890 | 940 | ||||

A | 176 | 194 | 280 | ||||||||||||

480 ~ 1000 | H | 445 | 480 | 670 | 740 | 780 | 850 | 860 | 880 | 930 | |||||

A | 176 | 194 | 280 | ||||||||||||

600 ~ 1500 | H | 445 | 570 | 600 | 820 | 890 | 950 | 1000 | 1100 | 1200 | |||||

A | 85 | 96 | |||||||||||||

1000 ~ 2500 | H | 445 | 570 | 600 | 820 | 890 | 950 | 1000 | 1100 | 1200 | |||||

A | 85 | 96 | |||||||||||||

Weight kg | 26 | 37 | 42 | 72 | 90 | 114 | 130 | 144 | 180 | 200 | 250 | ||||

Pressure pipe connector thread | M16X1.5 | ||||||||||||||